FOGGING artificial synthetic leather test is mainly for volatile substances condensed on glass, or aluminum foil, a test method. The light transmission method can be used or the weight method, the weight method is easy to operate and more widely used, generally within 2mg to meet the standard.

The content of volatile substances in automotive interior accessories is an important factor that affects the interior environment and driving visibility of automobiles. In the process of production and functional improvement of car interior accessories, small molecule substances are likely to be introduced into them, and the introduced substances are volatile, especially when the temperature inside the car is high. The small molecule substances volatilized in the car interior or floating in the air, polluting the air environment inside the car, endangering human health after being inhaled, or condensing on the car windows, adversely affecting the driving line of sight and threatening driving safety. Therefore, how to test the content of volatile substances in the interior parts of the car is a common concern in the automotive industry. Today Bensen gives you a detailed introduction.

● The history of volatile fogging performance testing:

1992, German Automotive Standard Committee and Synthetic Materials Standard Committee issued a standard, DIN 75201

1994, American Society of Motor Vehicle Engineers, SAE J1756

2000, International Organization for Standardization, ISO 6452

2005, Chinese Standard QB/T 2728

On the fogging test standards have not yet reached a unified international regulations, you can understand each test method to choose the appropriate local environment after the test method.

● The hazards of leather volatile fogging and the significance of detection:

1. Volatile gas in the car windshield or window condensation, resulting in poor visibility, affecting the driver’s vision and driving safety.

2. Some volatile substances are harmful to human body and affect the health of drivers and passengers. Reasonable control of volatile substances, volatile fogging performance (also known as fogging performance) test of materials used in automotive interior is very necessary, fogging value exceeds the standard indicators of the material will not be used for automotive interior.

Artificial leather due to the role of natural and man-made and other factors, the surface will appear cloudy or boundary blurred sheet secretions, called leather “cream”. Such as leather rainy days, synthetic leather will precipitate white powder (“salt cream”); leather contains a lot of fatty acid substances, then leather products in certain conditions will likely appear “oil cream” blemish; and leather “sulfur cream “also known as leather cancer, very difficult to overcome; leather for a long time in the preservation of easy to grow mold environment (high temperature and high humidity ventilation, containing nutrient source stains, etc.), its surface will appear with a variety of colors (gray, yellow brown, blue green) mold spots, called “mold cream”.

● The causes of the four types of cream

Salt Cream

Salt Cream

Because the leather is not fully washed after neutralization and before the drum, there are a lot of soluble salts in the leather, such as salt, mannite, alum, baking soda, etc. These soluble salts are dissolved in the moisture in the leather, and will form “salt cream” on the leather surface layer after drying, or exist in the crystal state between the leather fibers, and will migrate to the leather surface layer when encountering moisture. When wet, it will migrate to the skin surface layer to form “salt cream”. If you wipe off the “salt cream” on the leather, it will appear again when it is wet, and when you iron it with a hot iron, the “salt cream” is not absorbed by the leather.

Oil Cream

Oil Cream

Leather is constantly undergoing dynamic processes of exhalation and inhalation with the outside world during storage or use. The water vapor molecules in the leather carry the saturated fatty acids and their esters between the collagen fibers to migrate to the leather surface, and condense into “oil cream” white spots. Generally “oil cream” will appear in the raw leather in the fatty parts. The reason is that the leather manufacturing process degreasing is not sufficient, or in order to improve the feel of the leather surface used solid paraffin, solid silicon, advanced fatty acids and other high melting point fat liquor can not be absorbed by the leather uniform substance, or leather with oily maintenance in the wax component more, into the pores, etc., in storage and use process easy to migrate to the leather surface, forming ” oil cream”.

In the tanning industry, most of them use ash-alkali method to remove hair and soak ash, in which a large amount of NaHS and Na2S are added, and these substances are oxidized in the subsequent series of processing to produce S monomers between the leather fibers, thus producing the recessive pathogenic gene of “sulfur cream”. When the leather is dried naturally or baked at high temperature, “sulfur cream” does not appear, and S has a filling effect on the leather, which can reduce the adhesion of collagen and make the leather feel rich, soft and fine grain, etc., but because S monomers are not resistant to high temperature, so when it encounters high temperature, S will run out, and after cooling, it will crystallize on the leather surface and form “sulfur cream”. Formation of “sulfur cream”. Because the monomer S has very good stability at room temperature, strong acid, strong alkali, strong oxidizing agent, strong reducing agent at room temperature can not react with it, and it is slightly soluble in water, so this cream once formed is very difficult to overcome.

The growth of mold on leather has the following three reasons. First, leather contains a nutrient source of mold growth. As we all know, leather for the natural polymer compound processing products, its main components are collagen protein and fat, in the processing of leather, also added a large number of animal and plant oils and fats, inorganic salts and minerals and casein, etc., these are good sources of nutrients required for the growth of mold. Second, the presence of a large number of mold spores in the air. These mold spores float with the wind, with the encounter, once they fall on top of the leather, due to access to rich nutrition, very easy to grow and reproduce. Third, the leather processing and storage and transportation conditions, conducive to the growth and reproduction of mold. Mold growth temperature, humidity and PH range is very wide, suitable for the growth of temperature 25 ~ 35 ℃, relative humidity is higher than 75%, PH value is generally between 1.5 ~ 11, the most suitable PH value is about 6.0. In the process of tanning, such as acid dipping, tanning, retanning and finishing, the billets and the finished leather are under acidic conditions, and the porous structure of leather leads to its strong hygroscopicity and high water content (the water content of finished leather is usually 14%~18%). Under the condition of hot weather and high air humidity in the south of China, leather and its products are very easy to grow mold, and in the north there is also the possibility of mold. The hot and humid environment in the storage and transportation process also provides favorable conditions for the long mold of leather.

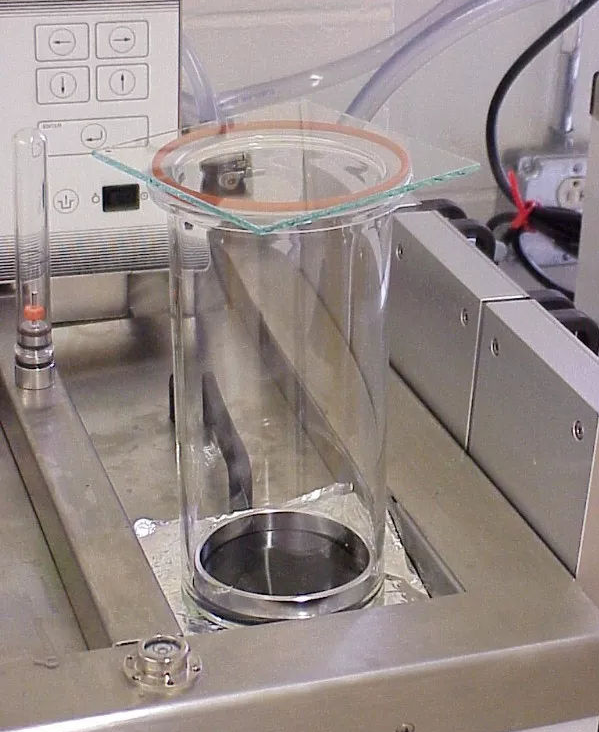

● The principle of volatile fogging detection

Automotive interior materials can be volatile substances volatilized into the air after heat, hot air encountered cooling objects, volatile substances and condensed into liquid attached to the cooling object. The process of fogging is the volatilization of substances – condensation process.

● Volatile fogging detection methods

1、Lusterity method.

Specimen in the fogging cup was heated by the evaporated gas condensed on the low-temperature glass plate, by comparing the gloss value before and after the condensation of the glass plate and calculate, the fogging value of the specimen can be derived.

2、Haze method.

Specimen in the fogging cup was heated by the evaporated gas condensed on the low-temperature glass plate, by comparing the haze value before and after the condensation of the glass plate and calculate, the fogging value of the specimen can be derived.

3、Weight method.

The gas evaporated from the specimen in the fogging cup is heated and condensed on the low-temperature aluminum foil, and the weight change before and after the condensation of the aluminum foil is weighed to obtain the weight of the fogging and condensation of the specimen.

● Leather “cream” solution measures

For leather “cream” problem, the key is prevention, Bensen company production of artificial synthetic leather focus on degreasing and each process of washing, to prevent the natural oil generated by the “cream”. At the same time, pay more attention to chemical materials into the factory testing and fat liquor formulation, with good bonding, small mobility of synthetic fat liquor and vegetable oil modified as the main fat liquor, the right amount of mineral oil to avoid or inhibit the occurrence of “cream”; anti-mildew should also be mentioned in the process operation and storage storage, add anti-mildew agent, warehouse ventilation, dry; control the temperature conditions To avoid the “cream” of the appropriate conditions appear.

The leather products used in daily life such as “salt cream” can be wiped with a towel that is wet and fully wrung out, and then wiped with emulsified shoe polish after drying. For the “oil cream” available ether or dry immediately after wiping with a soft cloth to remove. For “mold cream”, make sure to keep the products in a dry environment, low temperature, block the air, decontamination and keep clean. And “sulfur cream” because is called leather “cancer”, once formed it is very difficult to be removed, so only in the leather processing process to control.

Post time: Dec-15-2021